Rotary casting is one way of casting objects, and uses the centrifugal forces of the rotating cast in order to remove air bubbles from the cast object.

The Project

Ethical Solutions wanted to add additional value to their EVR Rotacaster rotary arm casting equipment by offering automatic (remote) control of the motors and a robust PC-based interface with a mould recipe database and mould run statistics.

Our Role

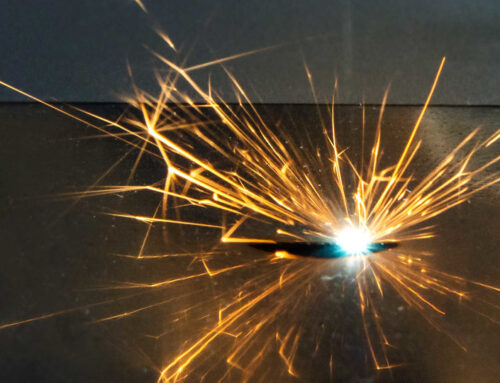

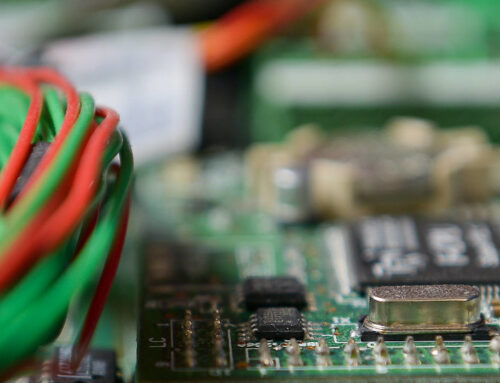

We delivered an easy-to-use bespoke software user interface, coupled with a compact SQLite database, associated programmable logic controller (PLC) and physical wiring (early prototype pictured above), to control the arm motors and provide automatic control of the EVR Rotacaster system.

LeoTel worked as a technology partner with Ethical Solutions to perform the use case modelling, design and implementation and integration of the PLC ladder logic, necessary circuit wiring and software user interface.

The Technology

A C#/.NET Windows application interfaced with the PLC using ModBus over Ethernet. Motor commands were transmitted between the PC-based software and PLC using a ModBus register-based model of the motors and system.

PLC ladder logic provided the ultimate control of the PLC controlling the primary and secondary arm motors, transmit to the motors via an RS485 interface.

A pair of contactless limit switches were developed in order to provide a “rock and roll” feature for the Rotacaster.

An SQLite database recorded mould recipes and run count.

The Benefit

We combined sound design practices with embedded software for reliable repeatable processes.

Our monitoring and control software is easy to use for non-technical staff, yet durable enough to withstand the industrial environment of a factory, and maximises profit and lifetime on existing lines.